Ten years after introducing the number-one Lambda Chain to the market in 1988, Tsubaki has developed innovative technology that sets the bar even higher for lube-free chain performance. To the user the benefits that X-Lambda provides mean increased productivity, reduced maintenance and a cleaner working environment.

Technical Evolution of BS Lambda

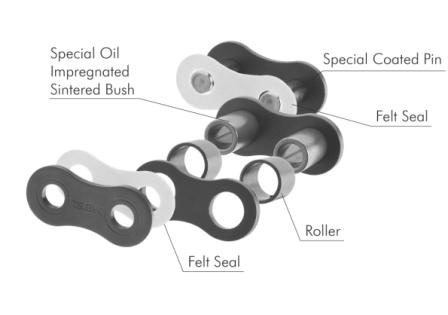

BS X-Lambda chain is a quantum leap for power transmission technology. The basic BS Lambda components (a special coated pin and NSF-H1 food grade oil-impregnated sintered bush) come completed with special felt seals (patent pending) between inner and outer link plate that lock in lubrication while keeping dirt and abrasives out.

Because of this evolution BS X-Lambda chain greatly increases the performance of the BS Lambda chains. When your operation needs to run clean, when machines and conveyed materials must be free from contact with oil, or when lubrication is difficult, BS X-Lambda chain can extend the life of your operation drastically.

Extended Wear Life

Even longer wear life than BS Lambda chain (over 5 times longer).

Applicable in Dusty Environments

Extra protection of critical areas due to the specially developed felt seal.

Connecting Method

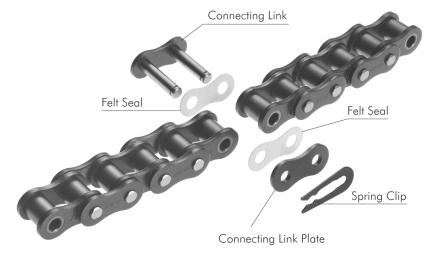

When connecting the chain, use a BS X-Lambda chain connecting link (with a felt seal). As shown in Fig. 13 insert felt seals between the outer plate and the connecting link plate, then attach the link.

Inter-Changeability

Chains:

Sprockets:

Find more detailed information about the BS X-Lambda chain here.